TC1 VIII Oct. 2011

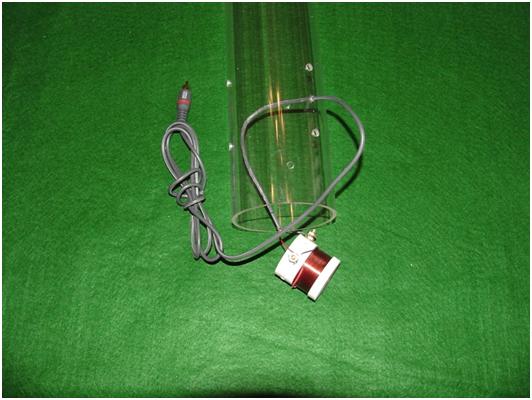

The original TC1 vertical seismometer was encased in 3″ ABS plumbing pipe.

This served two functions: (1) it enclosed the spring, protecting it from drafts;

(2)it served as a skeleton or frame on which the coil and damper were hung.

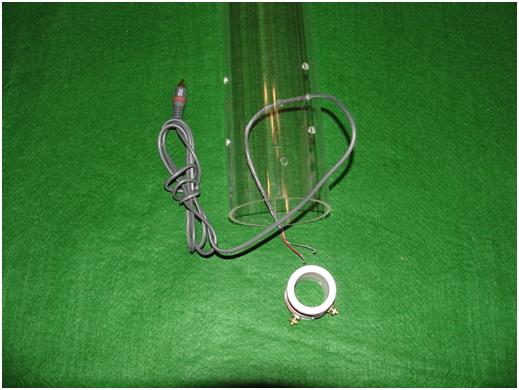

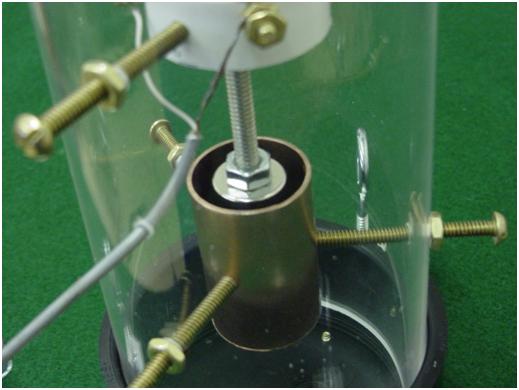

This version eliminated the ABS and the two ABS tees and replaced them with a single piece of 3.5″ OD acrylic tube, in this case 20″ long. 1/8″ wall thickness.

However, this could be any length you wish, which would give you a longer period. A 48″ or 60″ may require a heavier base to keep from tipping. You could also use a short section of acrylic and a longer section of 3″ ABS for a longer tube.

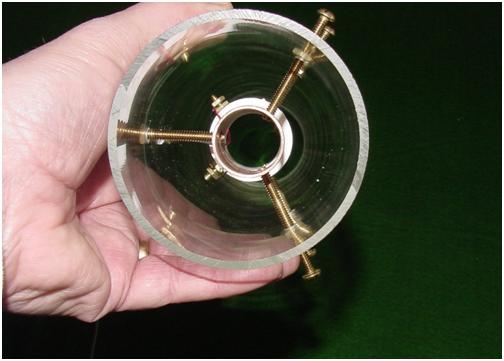

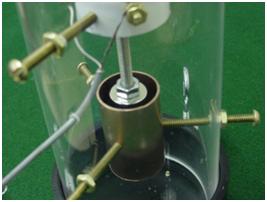

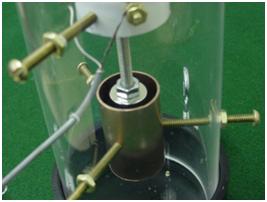

The coil and the damper are held in place using three each, #10 -24 x 2″ brass machine screws. The acrylic tube is drilled for these, using care not to crack the acrylic. On this 20″ tube, I drilled three for the coil at 5.0″ and three for the damper at 2.5″ from the bottom of the tube, all at 120 degrees, 7/32″ or ¼” bit.

You want a bit of play in the hole, so you can shift the part to the center line.

Drill a hole for the cable, to fit the cable diameter.

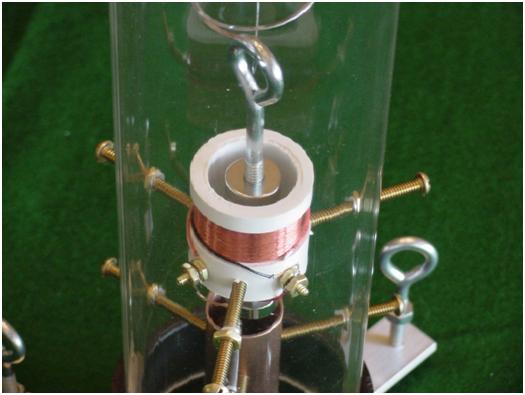

The coil is the standard Slinky type coil. In this case +/- 2500 turns of 38ga or 40ga copper magnet wire, and measured 700 ohms, to 2000ohms. The coil is made with a 3/4″ wrapped area.

The coil body is 1″ id and 1.75″ in overall length. It is made of PVC plumbing fittings, cut to fit. Note: Use any 1″ pvc fitting, like a coupler for the rings. Use the thinner wall pvc pipe, 200 psi, and not the thicker pipe, for the body.

The damper plate could be a cylinder ring of aluminum, 1″id x 1.5″od x .750″ tall.

Or copper, using a 1″ id copper pipe, cut 2″ in length, or 1″ copper pipe coupler which is precut to 2″ length. Both the coil and damper are drilled and tapped for 10-24, 2″ brass machine screws, three places each @ 120 degrees.

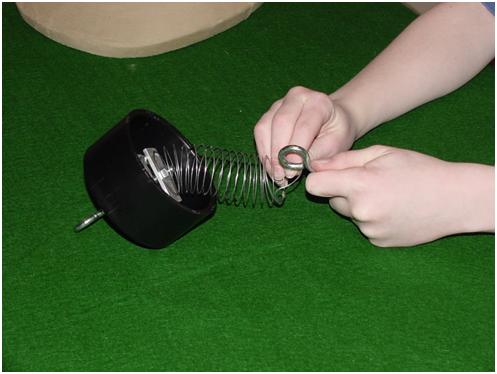

The spring assembly is made of a Slinky Jr. metal spring, cut in half in this case.

Use a full length Slinky Jr. spring for taller acrylic tubes. On this 20″ version, use approximately 15 of the coils. The remainder coils, retained with two alum, plates.

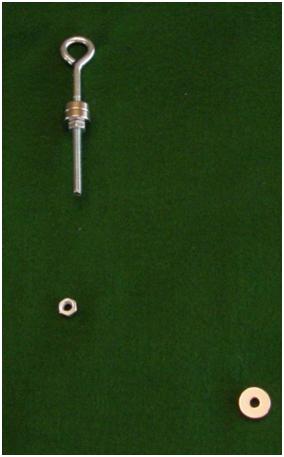

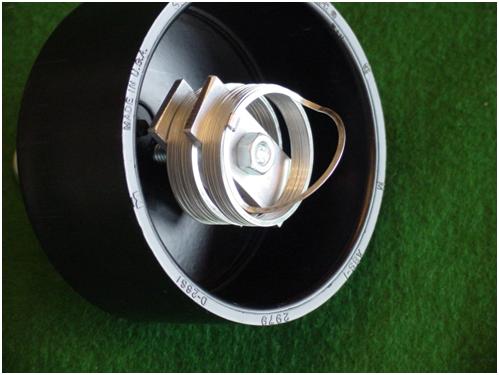

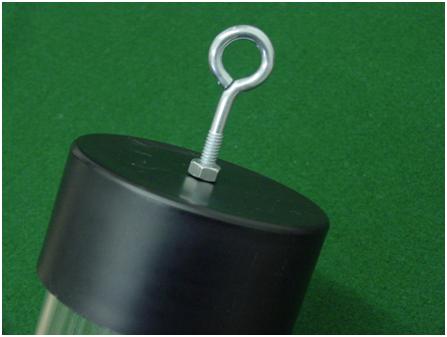

The spring is suspended from a ¼” 20 x 4″ eyebolt, nuts, and the 3″ ABS cap.

Use this eyebolt to make minor adj. to the magnet height.

A ¼”- 20 x 5″ iron eye bolt holds three RC44 ring magnets and adjustment nuts. This hooks over a loop made in the bottom of the spring. Make sure the all magnets are NSNS……..NS, and the two nuts are positioned as shown below on the magnets. This allows for positioning the magnets up or down the rod.

The neodymium magnets RC44, are ¼”id x ¾”od x ¼” thick. Two are used for the coil and one for the damper. The number of magnets used is optional. Their position on the threaded rod is adjusted using the adjustment nuts. On the coil both magnets should enter the top of the coil and the top of the top magnet should be even with the top of the PVC. This places one magnetic pole inside the coil and one magnetic pole outside. For the damper, the magnet should be even with the top of the copper, or ¼” inside. Proper damp is when the spring will bounce only once, or twice, not repeatedly.

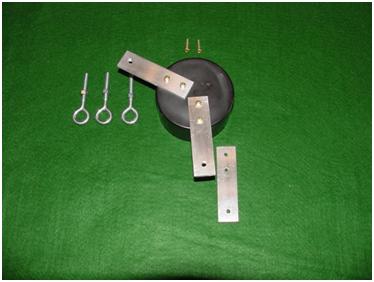

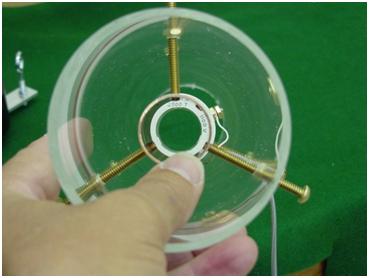

The legs and base are made using a 3″ ABS end cap. Drill and tap the cap, four places 8-32 for ¾”brass machine screws and a 1″ fender washer. The leg supports are made using 3/16″ x 1″ x 4″ alum. Drill one slip fit 5/32″ hole in each support, and angled the supports at 120 degrees. Drill and tap a ¼”x 20 in each support. The tapped hole is for the ¼”x20x3″ eyebolts and nuts for adj. legs.

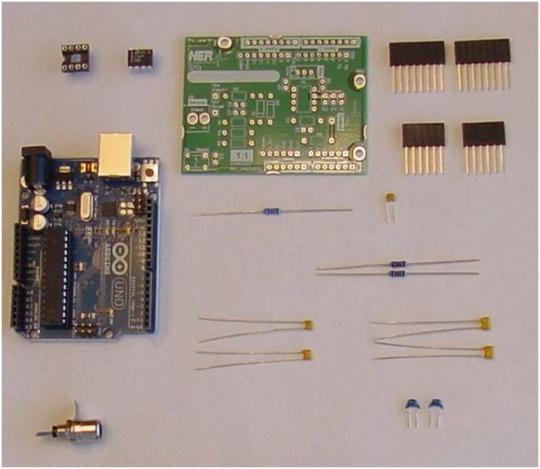

Bill of Material:

Qty. Size Description

1 3.5″od x 20″ Clear Acrylic tube. You can use 1/8″ or ¼” wall. This tube can be longer.

2 3″ ABS Pipe Cap

1 1.5″ Slinky Jr. metal spring, cut in half.

3 ¼” id x3/4″od x 1/4″thick RC44 Neodymium ring magnets.

1 ¼” 20 thread 5″ eyebolt” Threaded eyebolt, to hold the three magnets

2 ¼” 20 thread Iron magnet retainer nuts, for the magnets

3 ¼” 20 thread 3″ eyebolts. Adjusting legs, these can be thumb screws,

Or 3″ eyebolts, with nuts.

Or Black knobs, etc. about 2″ long.

6 10 – 24 x 2″ Brass machine screws and nuts

1 ¼” -20 thread 4″ eyebolt Eye bolt, washers, and 3 nuts for the top cap.

2 Flat stock ¾”x2″ Alum. Retainers and nuts for spring coils

3 Flat stock 3/16″x 1″ x 4″ Alum. Leg supports.

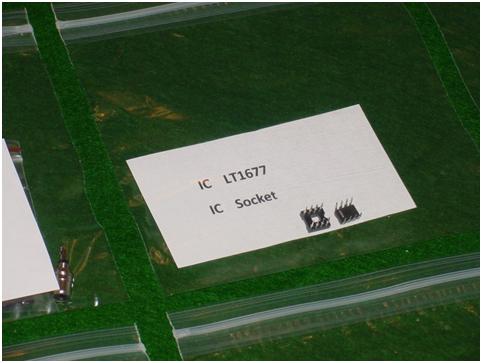

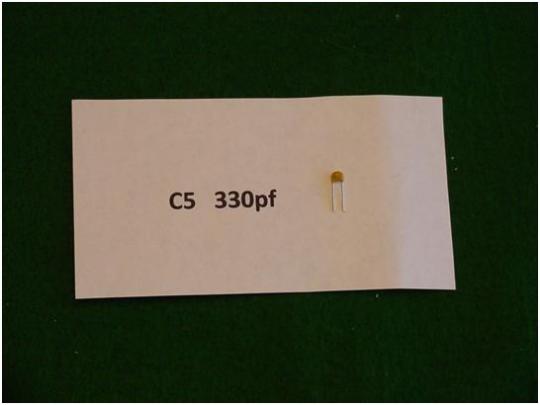

1 700+ ohms coil Appx. 2500 wraps of 38ga or 40ga copper magnet wire. I target 700 to 1200ohms, using 2500 wraps of 40ga.

1 1″ pvc pipe x 1.75″long pvc Coil body, 200 psi, stock

- Pvc ¼”ring to fit coil body Cut from 1″ pvc coupler fitting

1 Pvc ¾” ring to fit coil body. Cut from 1″ pvc coupler fitting

2 6- 32 x ¾” studs Brass terminals for coil wires

4 6- 32 Nuts Brass connectors for coil wires

1 1″id x 1.5″od x .750″ Damper dough nut cylinder aluminum,

Or 1″id x 2″length copper pipe or copper coupler

1 6-10′ RCA Cable RCA cable, one end male one end stripped

4 8-32 brass machine screws to attach alum legs supports to base cap.

1 1″ fender washer to attach alum legs supports to base cap.

Other parts as required.

.